1/128 Calibration Method

Why Use the 1/128 Calibration Method?

- Has the least amount of Calculations

- Easy to understand

- Easy to set up your sprayer

- Can be used on all types of spray equipment.

On Most Spray Equipment

- Spray pressure can only be varied a little.

- Large changes in the application rates can only be changed by replacing nozzles with larger orifices.

- The easiest thing to change is your speed.

1 / 128 Calibration Method

- Based on - 1 / 128 of an Acre per nozzle

- Based on - 128 ounces of liquid in a Gallon

- Results - ounces of liquid caught from one nozzle is directly equal to the application rate in gallons per acre (GPA)

Example

- If you catch 15 ounces from a nozzle, the application rate is 15 Gallons Per Acre (GPA)

Equipment Needed

- Tape Measure

- Stop Watch

- Graduated Measuring Jar - in Ounces

- Pocket Calculator

- 2 Markers - Flags, cones, stakes

8 Steps to Follow

Step 1.

Fill the Sprayer tank with Water

Step 2.

Run the sprayer, inspect for leaks, and Make sure all vital parts function Properly.

Step 3.

Measure the distance between nozzles.

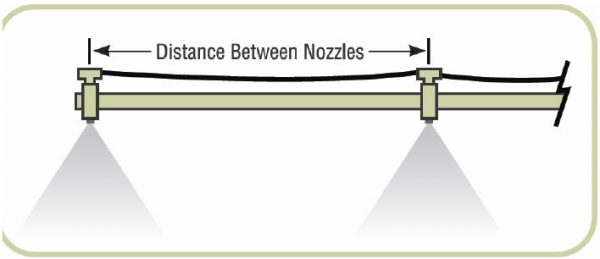

Step 4.

Then use Table 1(below) and Measure the distance in the field according to your nozzle spacing.

Step 5.

Mark off the distance and place a stake at both ends.

Step 6.

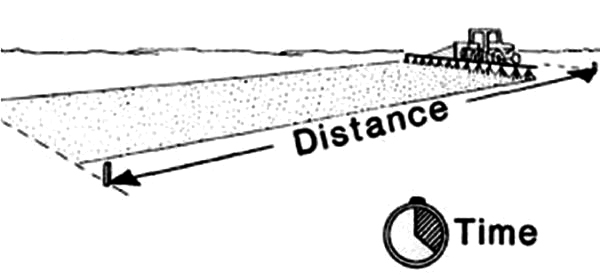

Drive the measured distance at normal speed, recording the travel time in seconds.

Step 7.

Park the Sprayer, run the sprayer, catch and measure the output from each nozzle the same time as in step 5

Step 8.

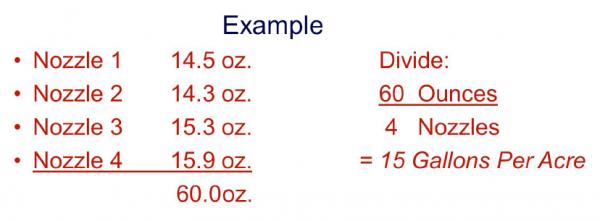

Calculate the average nozzle output by adding all individual nozzle outputs and dividing by the number of nozzles tested.

Average Output

Average output (ounces) = Application Rate (GPA)

Example: 15 Ounces per nozzle = 15 Gallons Per Acre

- The final average output in ounces is equal to the application rate in gallons per acre.

Things to Consider

-

If the individual nozzles are 10 percent higher or lower than the average, clean clogs or clean tips or replace nozzles.

-

Slower speeds mean more spray is delivered, faster speeds mean less spray is delivered.

-

Recalibrate the sprayer after any adjustment.

Review the Steps

- Fill the Sprayer tank with Water

- Run the sprayer, inspect for leaks, and make sure all vital parts function Properly

- Measure the distance between nozzles.

- Then use Table 1 and Measure the distance in the field according to your nozzle spacing.

- Measure the distance and place a stake at both ends.

- Drive the measured distance at normal speed, recording the travel time in seconds.

- Park the Sprayer, run the sprayer, catch and measure the output from each nozzle the same time as in step 5.

- Calculate the average nozzle output by adding all individual nozzle outputs and dividing by number of nozzles tested. This equals your gallons per acre.